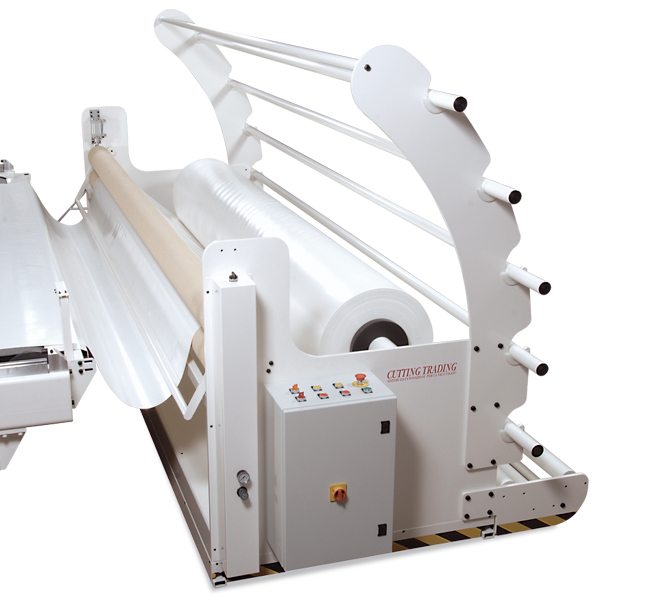

BTF UNWINDER

BTF UNWINDER

The unwinder has been designed to unwind and align rolls of heavy fabric which with other equipment like the cradle or the spreader could not be unwound. It also detaches plastic fabrics which stick to the roll.

Can be interfaced with any cutting machine.

The particular supply system permits adjusting the tension of the fabric so it remains uniform for the entire feed length. The high operating speed and a large load capacity make it the perfect tool for easily unwinding PVC and technical textiles with high rigidity. The possibility exists of fitting a self-aligning roll cradle for a single roll with max diameter 300 mm and, if required, a 5-roll rack.

TECHNICAL FEATURES:

- Unwinding of heavy fabrics

- Maximum speed 0.5 m/s

- Simple to load

- Load capacity 1,500 kg

- Independent operation

- Automatic alignment

- Fabric recovery option

- high fabric capacity up to 3.5 meters

Book your free online demo

You can connect via Skype with our agents,

view our products including technological devices and cutting systems and witness live cutting tests on the most varied types of materials.