Digital Cutter

RAPTOR HI 2.5 THE CUTTING EVOLUTION

AUTOMATIC MULTIFUNCTION CUTTING

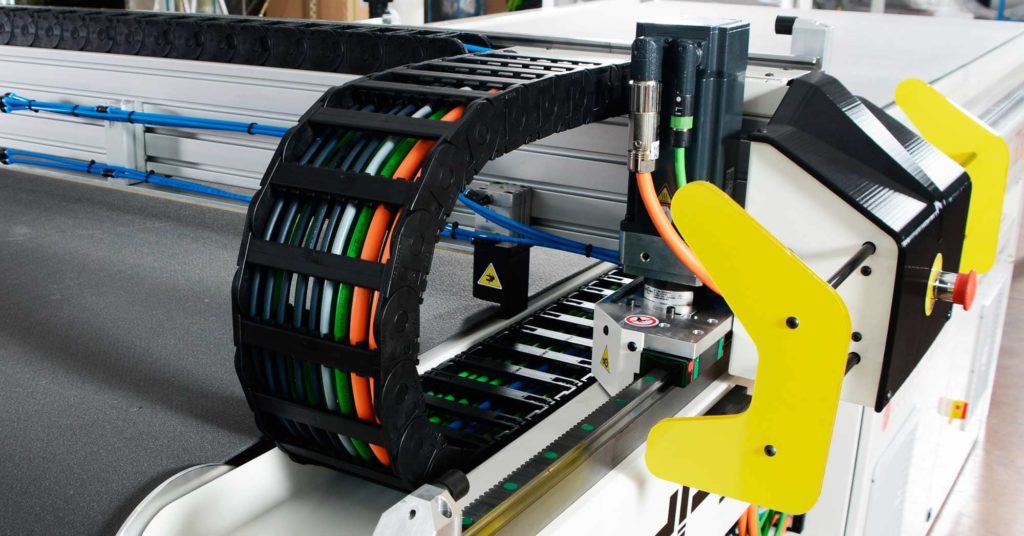

Cutting Trading International multifunction cutting consists of a compact and sturdy machine with a modular system for extensive cutting options.

Request information Download brochure Online Demo

HI RAPTOR 2.5

Robust construction and reliable movements of the head allow the achievement of high productivity and a high quality of cut.

It is designed to provide maximum performance in single ply cutting operations on most materials, can be supplied as a single ply conveyor or single ply static. Innovative solutions as “quick release” system for easy and fast tool replacement, gives our system a wide flexibility of use.

The specifically designed carpet of the single ply automatic cutting table increases the friction with the material and gives you energy savings up to 70%.

Hi Raptor can lodge up to five different tools at he same time, making it extremely versatile and suitable for every type of application.

The versatility of the HI Raptor system is based on wide availability of tools, the cutting dimension of which can be adjusted electronically.

This unit can work with a broad range of materials using the basic machine with specific tools for each type of operation with rapid switch from one material to another.

The sturdy construction and the reliable head movement together with high cutting speed and a powerful extraction system ensure high productivity and superior cutting quality.

HI RAPTOR 2.5

AUTOMATIC SINGLE-PLY CUTTING

Automatic single-ply cutting by means of a special belt structure, which increases friction with the fabric and permits air transpiration, creating a system that generates vacuum with low energy consumption with energy savings of up to 70% compared to a traditional cut without any need for cartene and paper.

HI Raptor features a highly intuitive interface for the use and operation of all controls and is easy to integrate with CAD-CAM solutions in an independent or shared way.

Thanks to direct connection to a local network, it is able to save finished jobs for later use. What is required of an automatic cutting system is extensive flexibility and slim management operations. HI Raptor cutting, thanks to the possibility of installing up to 5 tools simultaneously, becomes extremely versatile and suitable for every type of application.

Also standard on all automatic cutting is a laser pointer, an indicator of the cutting start point, and a pen which allows making markings useful for subsequent jobs.

Request information Download brochureTechnical features

- Static or conveyor cutting table

- Modular tools

- High cutting speeds up to 1500 mm/s

- High precision cutting

- Soft movements and reduced noise

- Compatible with DXF, HPGL, ISO formats

- Software configuration according to materials

- Cutting up to 50 mm thick

- Powerful suction system

- Excellent cutting quality

- Communication with CAD-CAM systems

- Large cutting window

XXL HI RAPTOR 2.5

XXL Hi Raptor 2.5, an innovative solution for the cutting of large and super large formats, able to answer to increasingly sophisticated customer requests and characterized by the possibility of customizing material cutting.

Thanks to the ability to customize the dimensions, we reached the remarkable size of 12 x 8 MT.

Book your free online demo

You can connect via Skype with our agents,

view our products including technological devices and cutting systems and witness live cutting tests on the most varied types of materials.